| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

PDS PROFİL DİLME SAC MAKİNALARI SAN. VE DIŞ TİC. A.Ş.

TEPEÖREN TUZLA OSB 8. CAD. NO: 1 KAT: 1 P.K. 34959 TUZLA / / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 593 3930

|

Hall: 7

Stand: 727/B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

PDS Makina, which is located in the Industrial Zone in Tuzla, Istanbul, has been engaged in providing turn-key sheet metal processing machines with its experienced and dynamic team that has been active in the sector for long years. Since the Group of which it is a part of manufactures semi-finished products, the company has obtained vast experience and fund of knowledge and used these in machine manufacturing which consolidated its corporate power and know-how even more. The company is unique in the world as it both manufactures the products and the machines which produce the said products. Moreover, PDS Makina attaches great importance to R&D (Research and Development) activities with intent to manufacture cost-effective and top quality products which can compete in the world market. Whereas our company, which has been awarded and supported by TUBITAK (THE SCIENTIFIC AND TECHNOLOGICAL RESEARCH COUNCIL OF TURKEY) for many of its projects carries out its designs and analysis with the hi-tech 3D Cad Software and its production with CAM software. Our company shares its experiences with its customers by means of offering the most rational and efficient solutions regarding consultancy, site selection, basic construction, employee training, installation of lines and operational assistance. PDS Makina always backs up its customers with its after-sales support such as providing technical service and spare parts. We owe a debt of gratitude to our customers who relied on our company and supported us and led us to success in terms of quality and customer satisfaction.

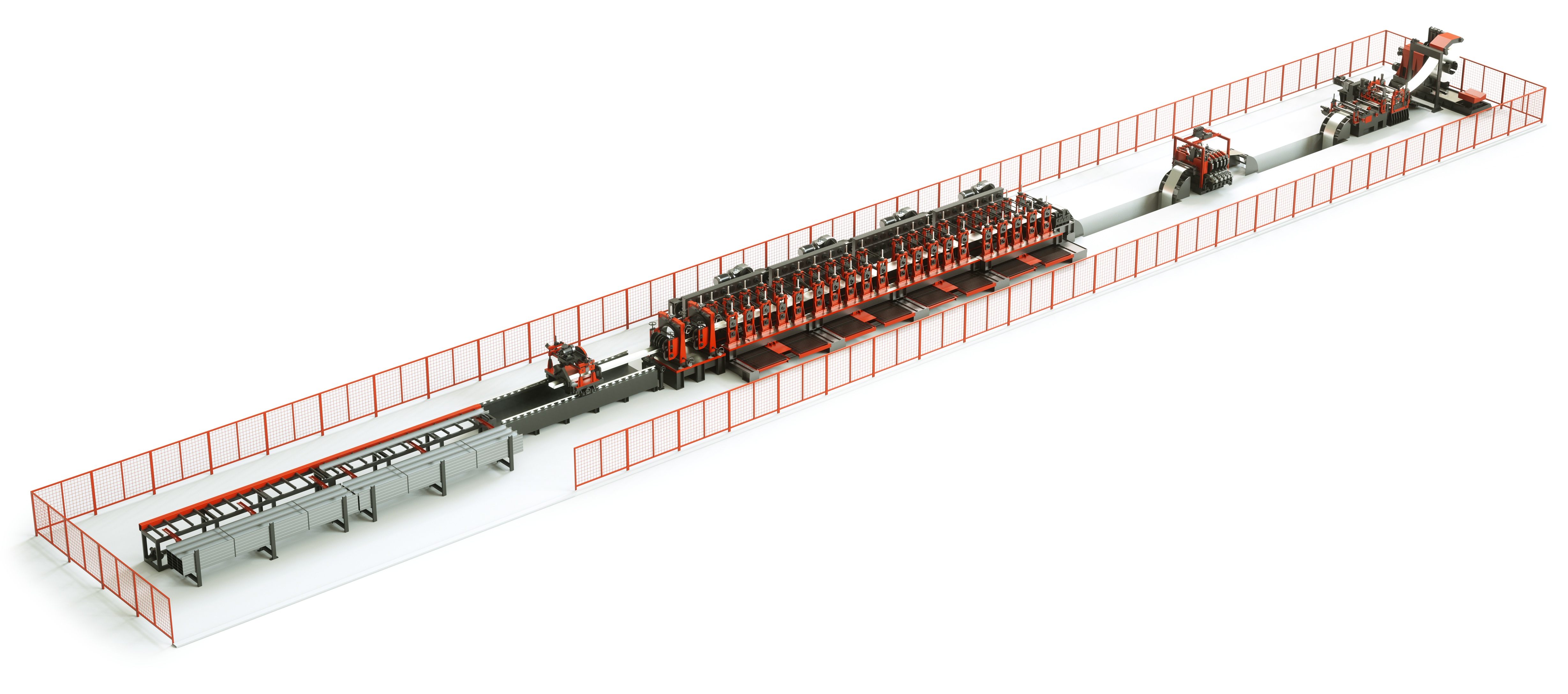

PDS Makina manufactures machines which produce different tubes varying between diameter of Ø8 and Ø219 mm, and square profiles varying between 10x10and 175x175, and rectangular profiles between 10x15 and 150x200. The company also offers high speed, quality production and fast mold changing opportunities.

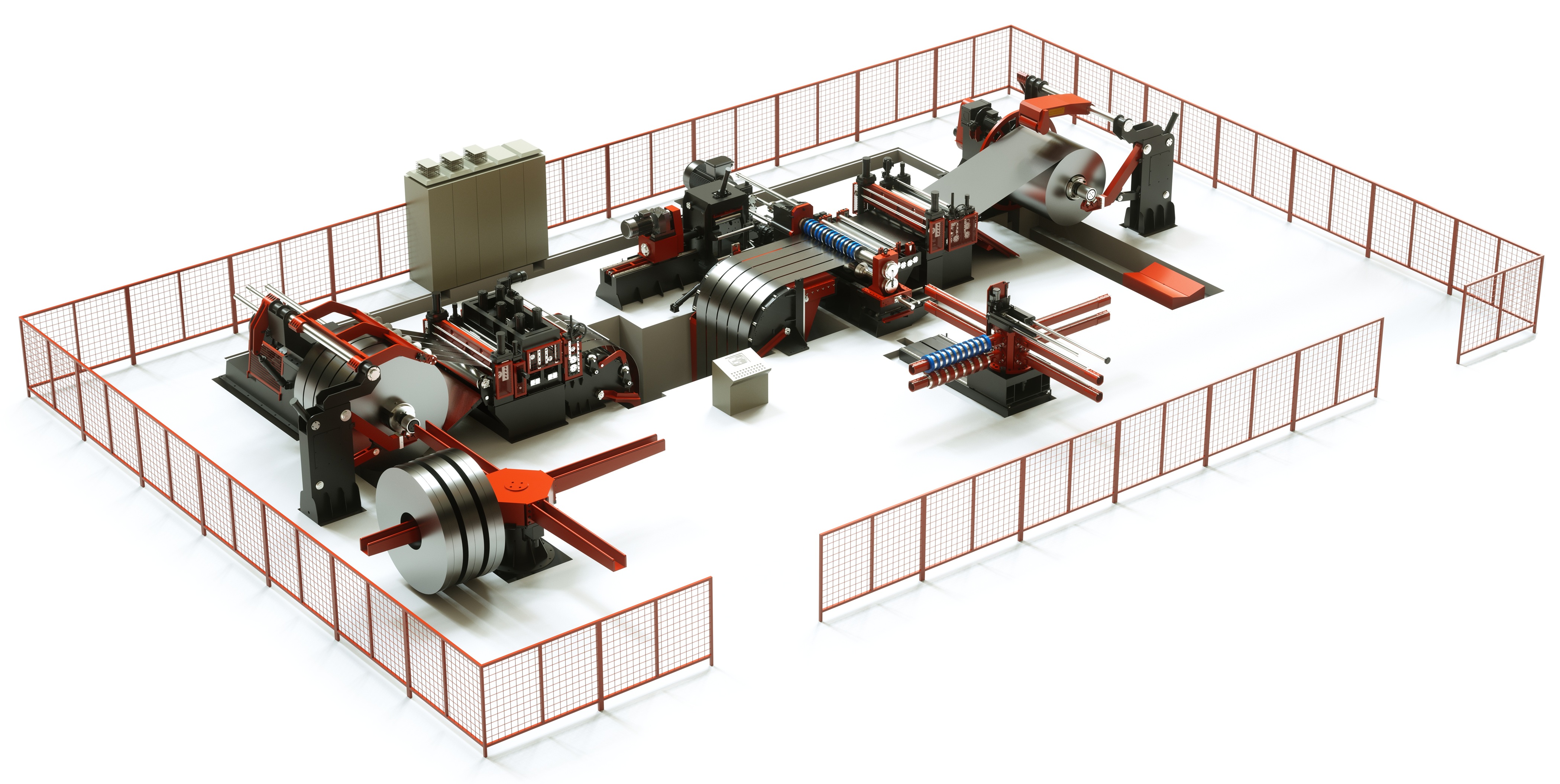

PDS Makina s slitting lines; uncoil the coils, slit the coils into strips by circular slitter knives positioned at certain intervals and recoil these strips. Slitting lines are designed to provide the best slit width tolerance and finest cutting for cold and hot rolled carbon steel, galvanize, stainless, aluminum, brass, copper and different special alloy steel coils of different width and weight between 0,3mm to 10mm thickness.

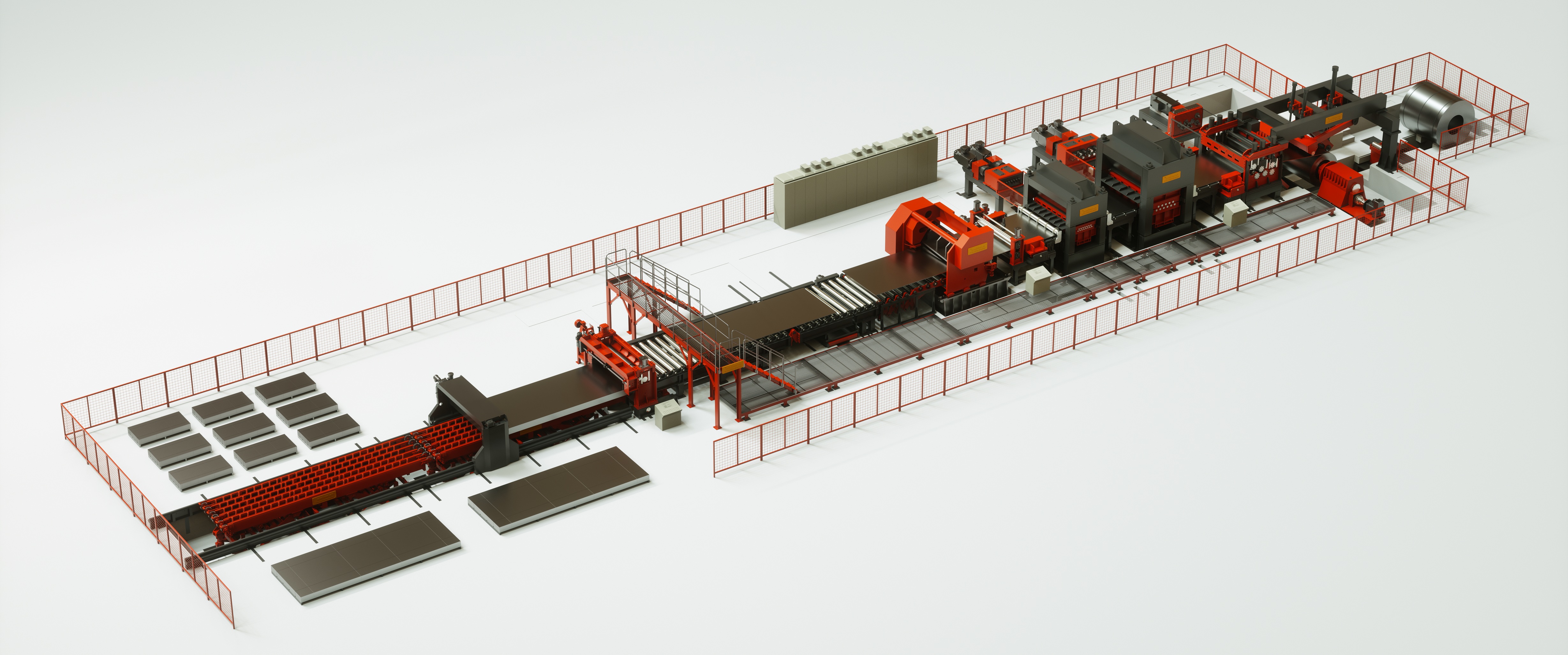

PDS Makina has been engaged in the production of top quality and efficient cut-to-length lines of various models and capacities. Coiled (rolled) raw metals are cut into sheets at desired lengths. Cutting process is carried out in accordance with the customer requirements with the appropriate levelers and rotary shear, flying shear or start-stop shear. Fully automatic packaging systems provide full automation.

In the Open Profile Line, sheets are produced in many various forms. In high-capacity production, the manufacturing process is completed with high-quality surface precision of open or closed profiles (clamped profile - hole profile - non-hole profile) and the least possible waste and the least labor force by saving time as well as with the combination of many processes. The most critical aspect of this technology is the process, thus the mold design. The design of rollform processing steps is developed with high experience on a pattern that is called a flower diagram, where all the bending passes are overlapped. It has a wide range of use areas from the light steel building industry to the warehouse, hangar profiles, container profiles, shelf profiles, solar energy systems construction profiles, greenhouse construction profiles, custom cross profiles, from custom stainless steel furniture profiles to furniture rails and slides and roof (coating) panels. According to customer needs, the rollform machine, mold design, and cassette systems are manufactured, and their spare parts needs are met.

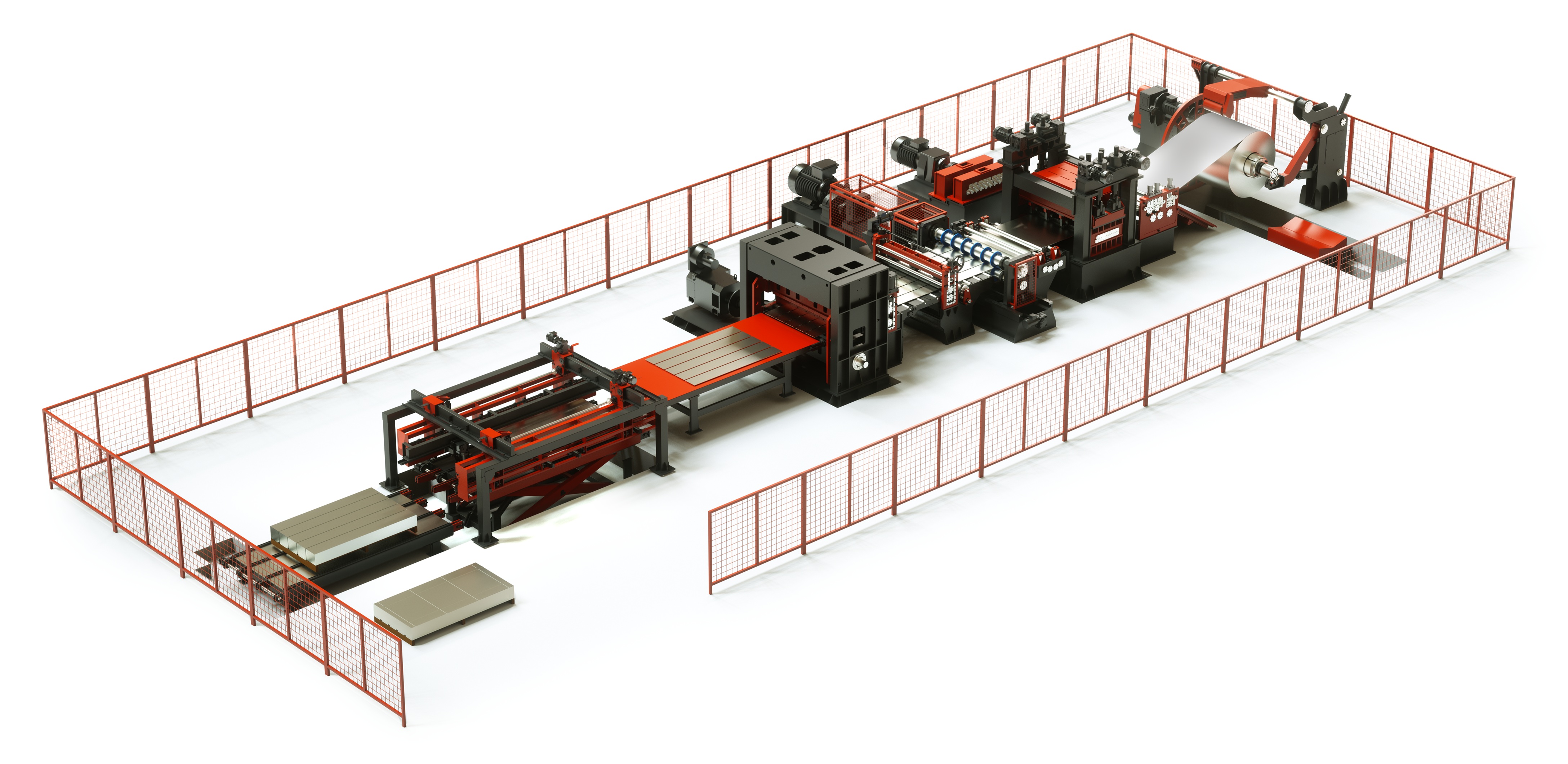

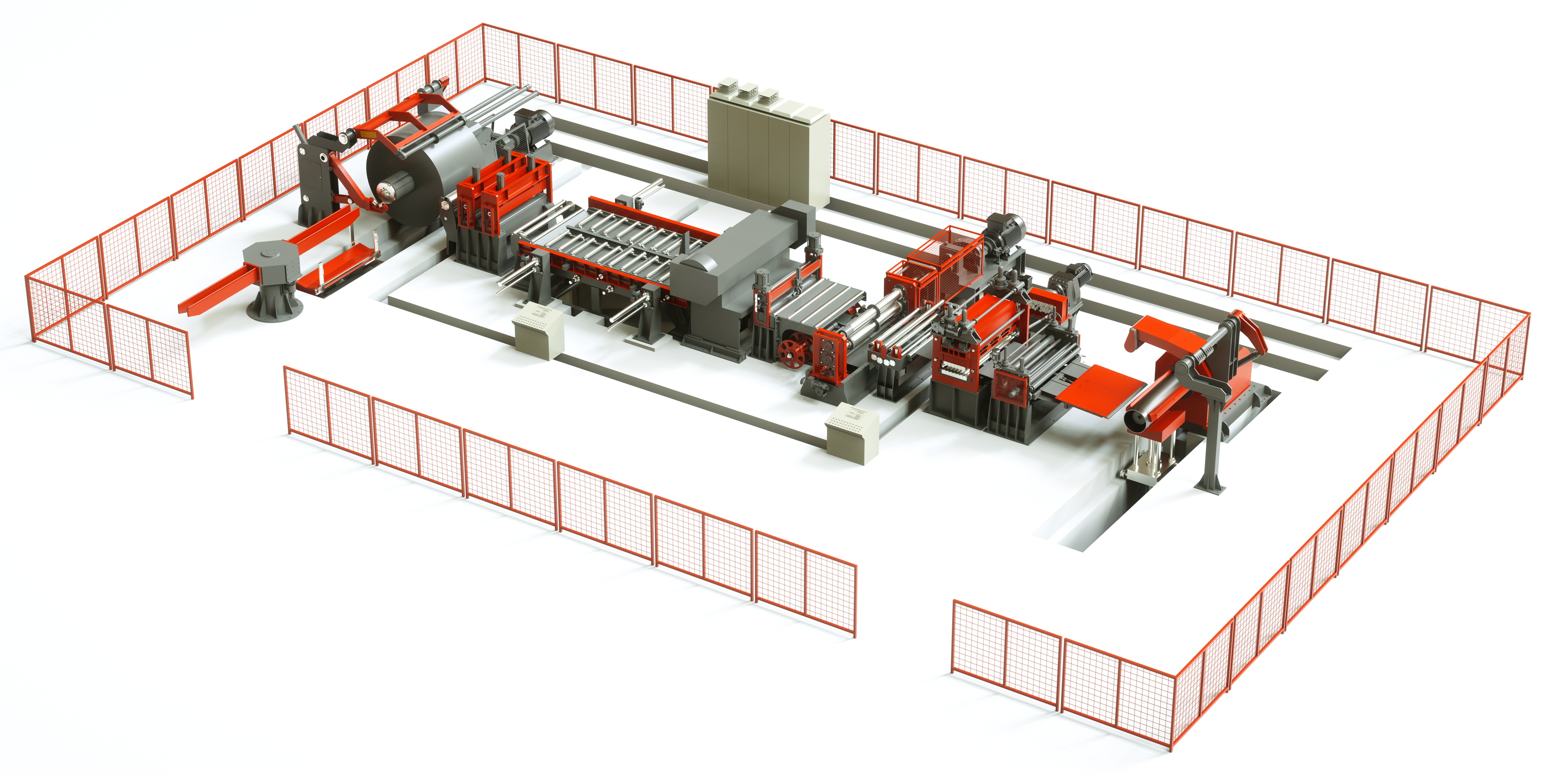

The PDS Slitting and Cut-to-Length Combination Line is a high-efficiency, high-production multi-cutting line that performs both slitting and cut-to-length processes on the same line. Recently, Service Centers have accelerated their investments in this type of equipment to meet increasing customer demands. Multi-cutting is a step beyond traditional cut-to-length processing in terms of both speed and precision. The Multi-cutting process involves uncoiling the sheet metal, slitting it, and cutting it into narrower plates. The PDS Slitting and Cut-to-Length Combination Line is particularly suitable for high-volume plate production, offering precise and efficient manufacturing. Slitting and Cut-to-Length Combination Lines come in various configurations. The most preferred system involves feeding the sheet metal from the Decoiler through a leveling unit for straightening, then slitting it into the desired widths. Finally, the cut-to-length process is performed, allowing multiple sheets of the same dimensions to be obtained simultaneously.

PDS Combination Slitting And Cut To Length Line is an efficient and high-volume multi-cutting line that performs both Slitting and Cut-to-Length operations on the same line. Service Centers have accelerated such investments in order to meet the increasing customer demands recently. Multi-Cut is a step up from conventional cut-to-length in terms of both speed and precision. The Multi-Cutting process is the cutting of the rolled sheet into narrower plates by opening and slicing. PDS Slitting-Slitting-To-Length Combination Line offers suitable and sensitive production especially for high-volume plate production. Slitting-Cut-To-Length Combination Lines have different configurations. The most preferred system, the sheet coming from the Uncoiler is first straightened by passing through the straightening unit and then sliced to the desired widths. Finally, the desired length cutting is done and thus more than one sheet metal of the same size is obtained at the same time.

No represented companies found.

- PDS PROFİL DİLME SAC MAKİNALARI SANAYİ VE DIŞ TİCARET ANONİM ŞİRKETİ

TR

TR