| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

LAP Measurement Technology GmbH

Zeppelinstr. 23 / / Lüneburg / GERMANY

|

Contact Info: +49 4131 951195

|

Hall: 8

Stand: 807/B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

LAP lazer projeksiyonu, lazerli ölçüm ve diğer yöntemlerle kaliteyi ve verimliliği artıran sistemlerde dünyanın önde gelen üreticileri arasındadır. LAP Measurement Technology GmbH, çelik sanayinde kalite denetimi ve proses optimizasyonu için lazerli temassız ölçüm sistemlerine odaklanmıştır. Şirket, hadde makinelerine yönelik lazer tabanlı ölçüm teknolojisi ve aksesuarlarıyla ilgili geliştirme, proje planlama, üretim, dağıtım ve servis hizmetlerinin yanı sıra uygulama odaklı danışmanlık sunmaktadır.

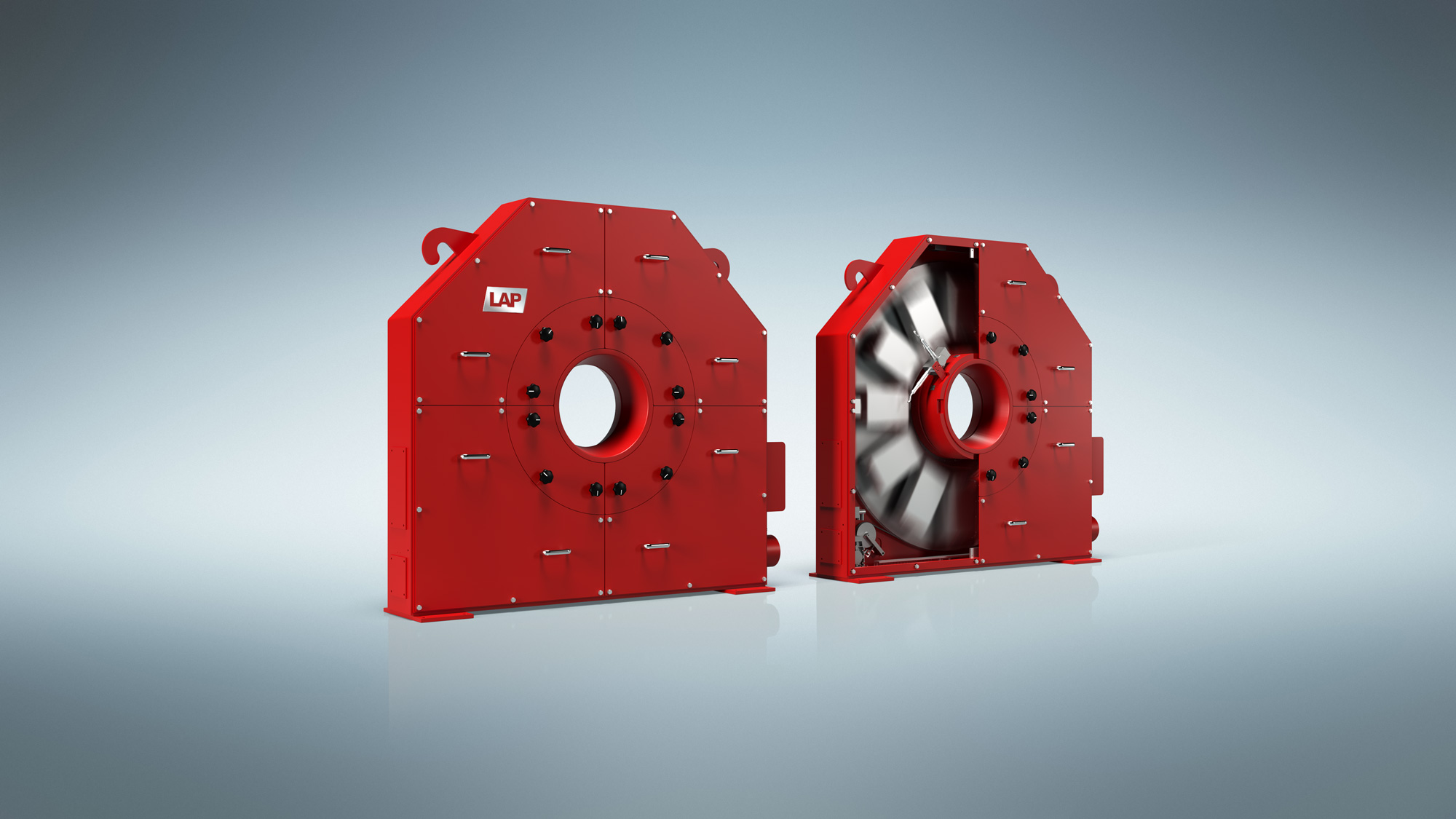

CONTOUR CHECK SHAPE is a laser-based measurement system for long products. The purpose of CONTOUR CHECK SHAPE is to control all dimensions and detect rolling defects during the production process of long products. The system can be applied for inline measurement of long products before and after a rolling stand and for both hot and cold material. Detection of geometrical deviations of nominal profile, rolling and surface defects Temperature stabilized setup Supporting various profile types Closed thermal design for extreme conditions

With our systems CONTOUR CHECK ROUND & EDGE you identify and evaluate deviations at an early stage. Increase the process efficiency of your production - regardless of temperature and profile shape. CONTOUR CHECK ROUND is the standard solution for dimensional measurement of round profiles and rebars up to 1200 °C. The versions with 3 or 6 axes can precisely measure round material produced by Y rolling stands. CONTOUR CHECK EDGE uses a set of sensors on an oscillating baseplate. In this way, square, flat, or hexagonal profiles can also be handled. The baseplate can also move to a certain angle position.

CONTOUR CHECK WIRE is a laser gauge profile measurement system that quickly and accurately quantifies the diameter for small round cross sections. In the version with 1 axis, it can precisely measure wires. The CONTOUR CHECK WIRE with 2 or 3 axes in an O-frame is even suitable for hot bars and reinforced bars.

4D EAGLE S combines classifying surface inspection with precise profile measurement in one powerful measuring gauge. Using laser light sectioning, the hybrid system accurately detects and classifies rolling defects and captures and measures the complete profile of long products. The measuring gauge jointly developed by KOCKS and LAP supports the path toward more efficient and transparent rolling. Advanced hardware technology, state-of-the-art software, and AI-powered machine learning open extensive analysis and evaluation possibilities for sustainable process optimization and quality assurance.

No represented companies found.

The company has no registered brand information.

TR

TR