| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Lämneå Bruk AB

Lämneå Bruk AB61273 Ljusfallshammar / / / SWEDEN

|

Contact Info: +46 122 232 00

|

Hall: 8

Stand: 826/G

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Established in 1727, Lämneå Bruk AB is a Swedish wire machinery manufacturer with nearly 300 years of expertise in the industry. Renowned for its highly customizable equipment, we specialize in designing and manufacturing machines for the ferrous and stainless-steel wire industry. From single machines to complete factories, Lämneå Bruk offers a comprehensive range of solutions, including pay-offs, rod preparation equipment, drawing machines, take-up units, and more. All parts and components are designed, developed, and manufactured in-house using advanced systems technology, ensuring the highest quality standards and full customization to meet specific industry demands. With a commitment to customer-centric solutions, innovation, and precision engineering, Lämneå Bruk combines its long-standing history with modern expertise to deliver maximum client benefits and profitability.

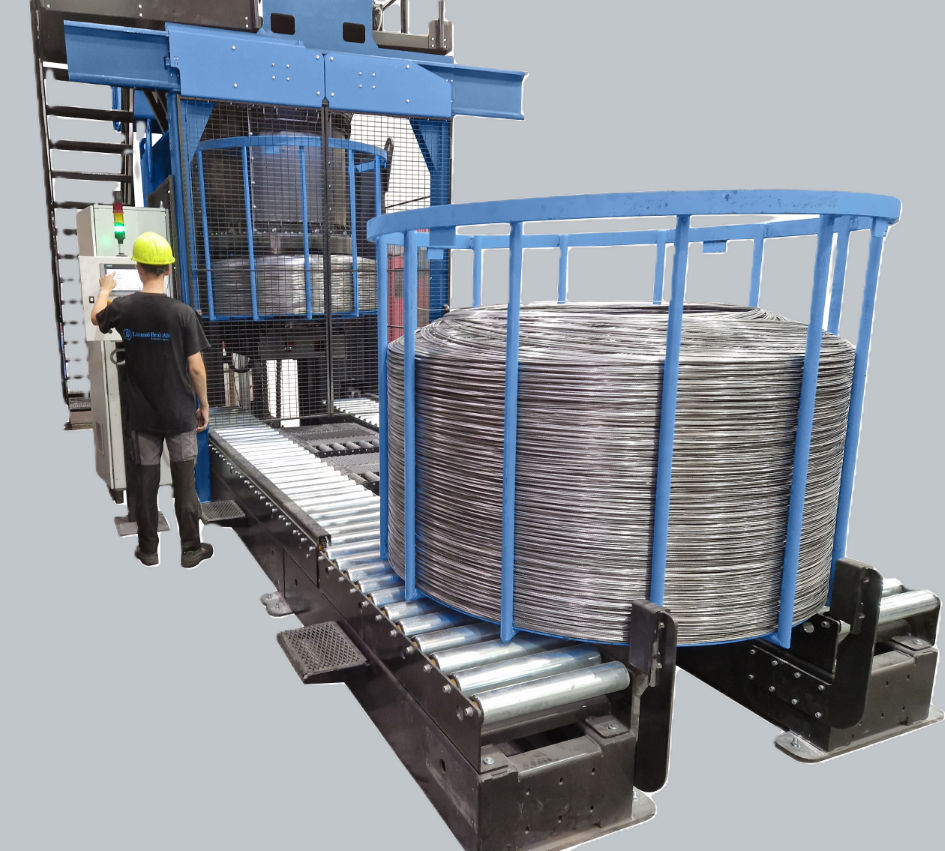

Launched in 1992, the No Twist Coiler (NTC), pioneered by Lämneå Bruk, continuously innovates wire production, with unparalleled wire production efficiency. The NTC significantly increases outputs during wire drawing and uncoiling without adjustments to existing setups. Ensuring twist-free wire for optimal utilization and minimal scrap, it accommodates all ferrous and non-ferrous wire types and drum sizes up to 4.5 tons.

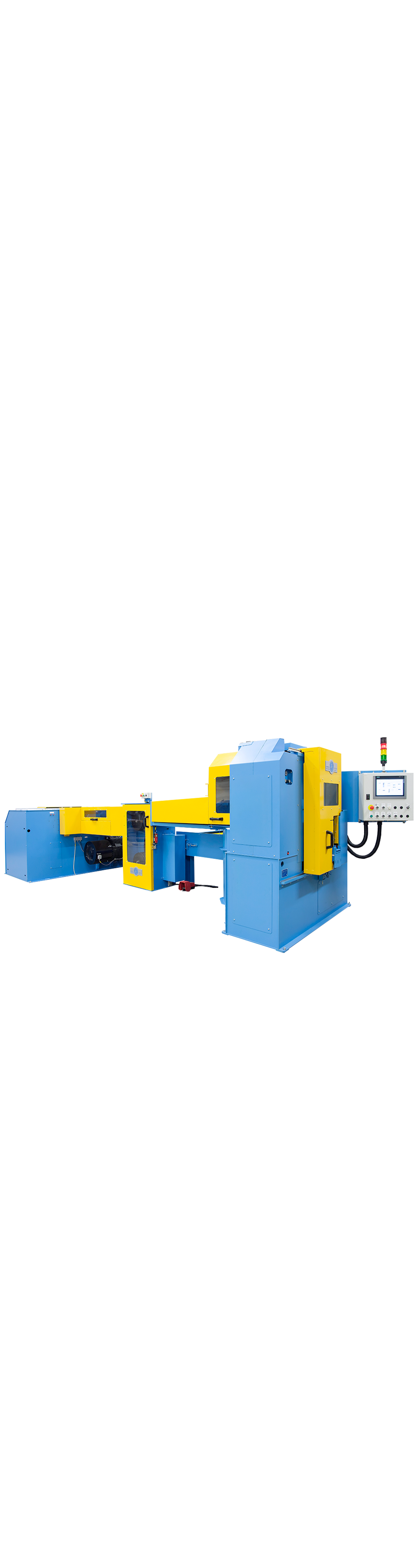

Our drawing machines cater to various wire types, from low to high-carbon, welding, to stainless-steel wires. Choose from top control system brands like Siemens, Mitsubishi, and Allens Bradley, depending on your preference.

Tailored for seamless automation, our innovative spooling, coiling, and rewinding portfolio, streamlines processes, ensuring efficiency and precision for every spool.

Our cutting-edge mechanical descaling portfolio is designed for continuous, and in-line descaling of wire rods, and effectively eliminates undesirable scale from the wire surface. Lämneå Bruk s Mechanical Descaling Machines offer a green alternative to chemical descaling. They prioritize environmental friendliness, while delivering efficient, space-saving, and high-quality rod cleaning, providing cost-effective results for your production needs.

No represented companies found.

- LäMNEå BRUK

TR

TR