| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

FİNE TEKNİK MAKİNA SAN. TİC. LTD. ŞTİ.

Eyüp Sultan Mah. Yadigar Sok. No: 40 OTOMER Galericiler Sitesi G/24 / Sancaktepe / İSTANBUL / TÜRKİYE

|

Contact Info: +90 505 790 3428

|

Hall: 8

Stand: 823/F

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Since 2017, in our own structure; We supply Machinery and Raw Materials for Wire processing, Twisting and Spring Manufacturing sectors. We serve as the authorized distributor of WNJ in Türkiye.

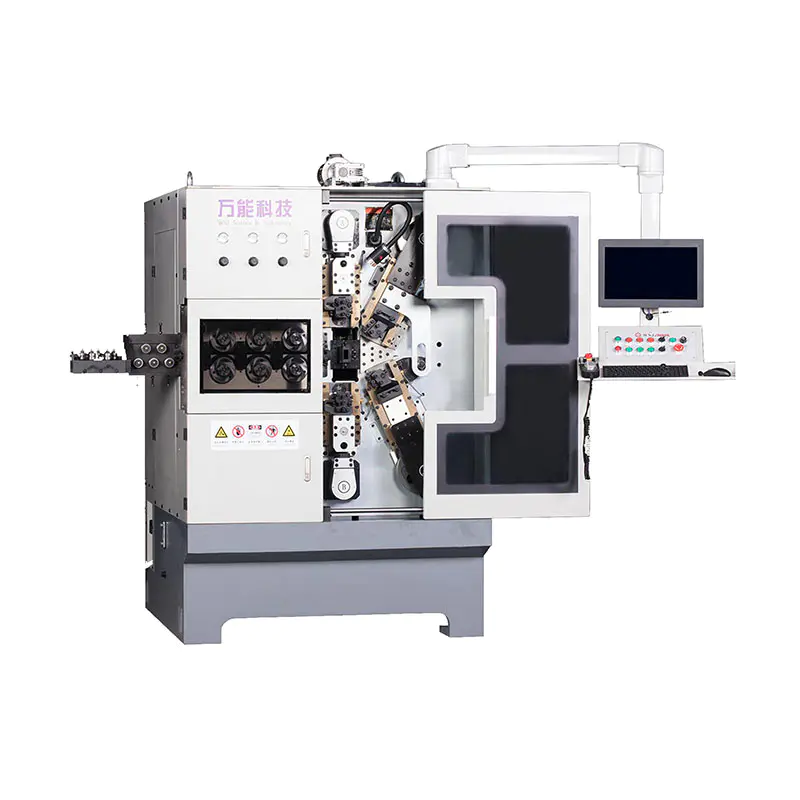

Wire diameter: Φ2〜Φ6 1. Controlled with six or seven axes: wire feed axis, pitch axis, upper variable diameter lower variable diameter, upper cutter axis, lower cutter axis and core pulling axis. 2. The six axes can work single-step or synchronously. 3. Computer interface displayed in Chinese and English which makes the operation easy. 4. Equipped with right and left rotation cutter frame. 5. Cutter can perform straight cut, opposite cut, twist cut and swing cut. 6. Computer has automatic programming functions.

No product info found.

These continuous temper furnaces are a kind of heat treatment equipment for mechanical spring industry and food industry that are deeply popular among customers. They adopt imported electrical components, stepless speeder, and have advantages such as energy saving(30% off compared with the similar products), rapid temperature raising(it can reach the required temperature within 20 minutes), uniform and stable temperature in furnace chest, high precision in automatic control, convenient for continuous working, good reliability, etc.

1. Adopts a camless and modular design, with fast adjustment speed, low noise. high accuracy, and good stability. 2. Controlled with ten axes, can work single-step or synchronously. 3. The slider adopts a precision linear guide mode and can be equipped with free hand, spinner and servo cutter. 4. Computer interface displayed in Chinese and English which makes the operation easy. 5. Can make special-shaped spring, torsion spring, tension spring and stationary products etc.

No product info found.

WNM9 CNC spring end grinding machine is the latest developed spring grinding machine based on the advanced CNC end grinding technology at home and abroad. It adopts servo motor to control the grinding wheel and has automatic inspection, compensation and alarming function. The feed speed, feed rate, grinding pressure feeding tray speed, all can be prog rammed on the computer. It s convenient to operate and has a high efficiency. lt is the ideal equipment for mass production of double-end grinding spring.

- FİNE TEKNİK MAKİNA SAN. TİC. LTD. ŞTİ.

TR

TR